3 Resin Grit Resin Grinding Wheel Optimized for Fast Material Removal and Smooth Surface Finishing in Metal Fabrication

Product Details:

| Place of Origin: | Guangdong,China |

| Brand Name: | PBLOG |

| Certification: | Low speed motor , high brightness |

| Model Number: | 150*12*20*12 Resin Grinding Wheel |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pc |

|---|---|

| Price: | 28USD |

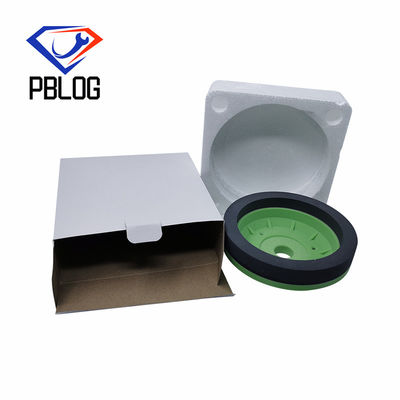

| Packaging Details: | Common Carton Box |

| Delivery Time: | 15days |

| Payment Terms: | 100%T/T |

| Supply Ability: | 40pcs/week |

|

Detail Information |

|||

| Features: | Thin Glass Grinding | Grit: | 3/4/5/6/7# |

|---|---|---|---|

| Diameter: | 150mm | Hardness: | High Hardness |

| Application: | Thin Glass Grinding | Max Speed: | Lower Than 2800RPM |

| Material: | Resin | Inner Hole: | 22mm |

Product Description

Product Description:

The Resin Grinding Wheel is a high-quality, high durable resin wheel specifically designed for precision thin glass grinding applications. Featuring a robust cup wheel shape, this grinding wheel is engineered to deliver exceptional performance and long-lasting durability, making it an ideal choice for professionals working with delicate and thin glass materials. Whether you are engaged in industrial glass processing or specialized glass crafting, this 150mm resin wheel offers the perfect balance of efficiency and reliability.

One of the standout features of this resin grinding wheel is its compatibility with double edge machines and beveling machines, two of the most commonly used machines in glass grinding and finishing. The cup wheel shape enhances the grinding process by providing a larger contact surface area, which ensures smooth and consistent grinding results. This makes the tool particularly effective for thin glass grinding, where precision and care are paramount to avoid damage or breakage.

Available in a variety of vibrant colors including orange, blue, and yellow, the resin grinding wheel not only offers aesthetic variety but also allows for easy identification and differentiation between wheels used for different glass types or specific grinding stages. The color coding is particularly useful in busy workshop environments where multiple grinding tasks are carried out simultaneously.

Measuring 150*22*15*14 mm, this 150mm resin wheel is perfectly sized to fit a wide range of grinding machines, ensuring versatility and ease of integration into existing workflows. The carefully designed dimensions also contribute to the wheel’s stability and precision during operation, reducing vibrations and improving the overall quality of the grind. This precise sizing makes the wheel a popular choice among glass manufacturers who demand consistent and high-quality finishes.

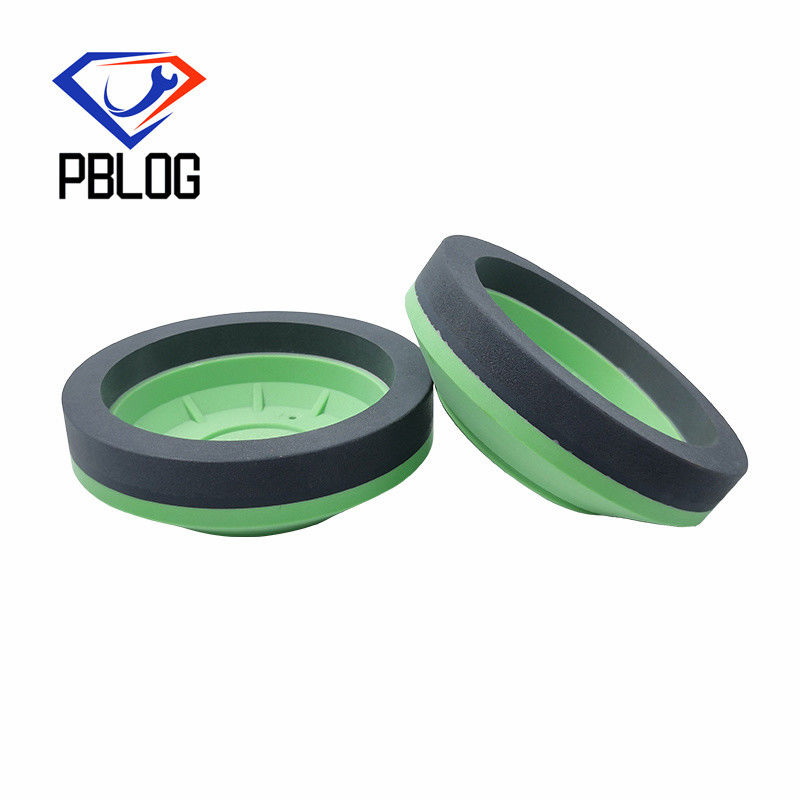

The green resin wheel variant of this product line is particularly noted for its enhanced abrasive properties and superior grinding efficiency. It combines the resilience of resin bonding with the strength of high-quality abrasive materials to deliver excellent cutting performance and extended service life. This makes the green resin wheel an excellent option for users seeking both performance and cost-effectiveness in their grinding operations.

Durability is a critical factor when selecting grinding wheels, and this high durable resin wheel excels in this regard. The resin bonding technology ensures that the abrasive particles remain firmly embedded within the wheel, reducing wear and tear and minimizing the need for frequent replacements. This durability translates into reduced downtime and lower operational costs, making it a smart investment for any glass processing facility.

Moreover, the resin grinding wheel is designed to maintain sharpness and grinding efficiency over prolonged use, which is essential when working with thin glass that requires delicate handling and precise shaping. Its ability to deliver consistent grinding results without causing micro-cracks or surface damage helps preserve the structural integrity of thin glass products, contributing to higher quality end products.

In summary, this resin grinding wheel is an indispensable tool for thin glass grinding applications, offering a combination of high durability, precise dimensions, and compatibility with double edge and beveling machines. Its availability in multiple colors including orange, blue, yellow, and the special green resin wheel variant ensures that users have the right tool for every stage of their grinding process. With its superior performance and long-lasting reliability, the 150mm resin wheel stands out as a top choice for glass grinding professionals seeking efficiency, precision, and value.

Features:

- Product Name: Resin Grinding Wheel

- Inner Hole Diameter: 22mm

- Application: Thin Glass Grinding

- Overall Diameter: 150mm

- Features: Thin Glass Grinding, Resin Wheel High Sharpness

- Compatible Machines: Double Edge Machine, Beveling Machine

- Type: Plastic Platform Resin Grinding Wheel

- Grit Size: 150# Resin Grinding Wheel

Technical Parameters:

| Product Name | Plastic Platform Resin Grinding Wheel |

| Type | 150# Resin Grinding Wheel |

| Durability | High Durable Resin Wheel |

| Advantage | High Brightness, Thin Glass Protection |

| Inner Hole | 22mm |

| Color | Orange / Blue / Yellow |

| Machine Compatibility | Double Edge Machine / Beveling Machine |

| Max Speed | Lower Than 2800RPM |

| Size | 150*22*15*14 |

| Hardness | High Hardness |

| Application | Thin Glass Grinding |

| Grit | 3 / 4 / 5 / 6 / 7# |

| Features | Thin Glass Grinding |

Applications:

The PBLOG 150*12*20*12 Resin Grinding Wheel, originating from Guangdong, China, is a high-quality abrasive tool designed for precision grinding and finishing tasks. With a diameter of 150mm and an inner hole of 22mm, this 150mm Resin Wheel is perfectly suited for various industrial and manufacturing applications where accuracy and surface finish are critical.

Thanks to its high hardness and advanced resin bonding, the 150mm Resin Wheel provides excellent durability and consistent performance. It is especially ideal for grinding thin glass, offering superior protection to fragile materials while maintaining high brightness and clarity of the finished product. This makes it an essential tool in industries such as glass processing, optical manufacturing, and electronics, where the quality of the glass surface directly impacts product performance.

The 150mm Resin Wheel’s low-speed motor compatibility ensures safe and efficient operation, reducing heat generation and minimizing the risk of damage to delicate workpieces. Its high brightness advantage further enhances visibility during grinding, allowing operators to achieve precise results with ease. This combination of features makes the PBLOG resin grinding wheel a reliable choice for detailed and high-quality grinding tasks.

In addition to glass grinding, this resin wheel is also widely used for metalworking, tool sharpening, and shaping hard materials. Its high hardness and thin profile enable it to handle tough grinding jobs while protecting the integrity of the workpiece. The common carton box packaging ensures secure delivery, and with a supply ability of 40pcs per week, customers can rely on consistent availability.

With a minimum order quantity of just 1 piece and a competitive price of 28 USD, the PBLOG 150mm Resin Wheel is accessible for both small-scale workshops and large production facilities. The delivery time of 15 days and payment terms of 100% T/T provide a convenient purchasing process. Overall, this resin grinding wheel is an excellent tool for those seeking high-performance grinding solutions with excellent surface protection and finishing capabilities.

Customization:

PBLOG offers customized Resin Grinding Wheel solutions tailored to your specific needs. Our model 150*12*20*12 Resin Grinding Wheel is manufactured in Guangdong, China, ensuring top-quality craftsmanship and reliability. Certified for use with low speed motors and designed to deliver high brightness performance, this Resin Wheel High Sharpness product is ideal for precise grinding tasks.

The Green Resin Wheel features a cup wheel shape with an inner hole size of 22mm and a maximum speed rating of lower than 2800RPM, making it perfect for thin glass grinding applications. Its high brightness and thin glass protection advantages provide superior results and durability.

We accept a minimum order quantity of just 1pc at a competitive price of 28USD per unit. Each Resin Grinding Wheel is carefully packed in a common carton box to ensure safe delivery. With a supply ability of 40pcs per week and a delivery time of 15 days, PBLOG ensures timely fulfillment of your orders.

Payment terms are straightforward with 100% T/T required, guaranteeing a smooth transaction process. Choose PBLOG for your Resin Grinding Wheel needs and experience unmatched quality and service from a trusted brand in the industry.

Support and Services:

Our Resin Grinding Wheels are designed to provide superior performance and durability for a wide range of grinding applications. To ensure optimal results and longevity of the product, please follow the recommended usage guidelines and maintenance procedures.

Before using the grinding wheel, always inspect it for any signs of damage or wear. Do not use wheels that are cracked, chipped, or otherwise compromised, as this may lead to safety hazards or subpar performance.

Mount the resin grinding wheel securely on the appropriate grinding machine, ensuring that it is properly balanced and aligned. Use the correct speed as specified by the manufacturer to prevent overheating or wheel damage.

Regularly clean the grinding wheel to remove any debris or buildup that could affect its grinding efficiency. Use appropriate cleaning tools and avoid harsh chemicals that could degrade the resin bonding.

Store the resin grinding wheels in a dry, cool place away from direct sunlight and moisture to maintain their integrity and prevent premature aging.

If you encounter any issues with the product or require technical assistance, please refer to the product manual or visit our support website for troubleshooting guides and FAQs.

For best results, always use the resin grinding wheel with compatible materials and adhere to recommended grinding parameters. This will help maximize the wheel’s lifespan and ensure consistent, high-quality finishes.

We are committed to providing excellent technical support and after-sales service. Should you need further assistance, our technical team is available to help with product selection, application advice, and maintenance tips.